- X-ray Generator

- X-ray Imaging System

- Microfocus X-ray Sources

- Industrial Computed Tomography

- Tube to Tube-sheet Welds Inspection System

- Pipeline Corrosion Inspection System

- Portable X-ray Machine

- Foil Sealing Machine

- Printing Machine

- JIMA

- Add: A1211, No.20 Gangwan Street, Zhongshan Dist., Dalian City, Liaoning Province, P.R.China

- Tel: 0411-82767933

- Fax: 0411-62287077

- Email: han@lind.cn

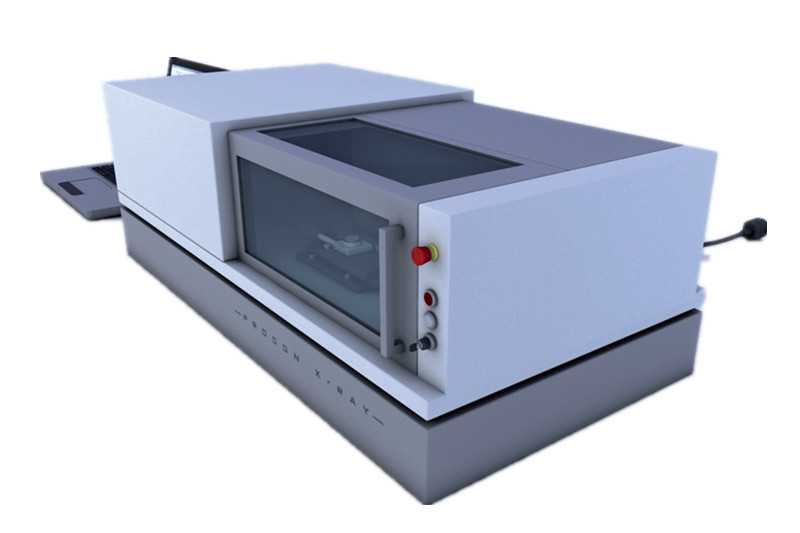

ProCon Micro Portable Industrial CT

- Model: CT-Portable

- Product description: CTportable is especially suitable for demonstration purposes as well as for mobile services or an application in arbitrary laboratories. The CT system can not only be utilized by universities or

Product introduction

A portable, easy-to-handle CT system

Recently the computed tomography (CT) became more and more important as a non-destructive inspection method for the industry. CT provides a fast visualization of a three dimensional volume model of the outer and inner structure of an object that can be interpreted even by laymen. However, up to now the acquisition costs and the relatively complicated operation often prevented a widespread adoption of computed tomography systems.In order to approach these problems the Fraunhofer Development Center X-Ray Technology EZRT developed CTportable, a mobile, compact tabletop system for the inspection of small objects made of plastics, textiles, ceramics, light metal, biological materials and the like.

The smallest mobile CT system worldwide

With its dimensions of approx. 350 x 300 x 230 mm (l x w x h) the space requirement of the CT system is minimal, moreover the low weight of approx. 20 kg ensures maximum mobility. Thus the CTportable is the smallest and lightest CT system in its market segment at present. These features enable the user to apply the system flexibly at any location without the necessity of transporting the samples or components to a laboratory.

High-performance microfocus X-ray tube

The integrated X-ray source with a maximum acceleration voltage of 50 kVp allows the inspection of solid specimens made of plastics or organic material up to the maximum geometrical object size. In case of metal components a lower irradiation length of e.g. approx. 10 mm in case of aluminum is possible. A geometric spatial resolution of up to 33 μm can be obtained due to a focal spot size of less than 50 μm and a possible magnification of 1.1 – 2. This allows e.g. the inspection of porous concrete.

Further characteristics

For demonstration purposes CTportable offers the possibility to observe the presently inspected object permanently through large lead glass windows. Nevertheless the CTportable is a fully shielded system.

An innovative cooling of the system guarantees a very low-noise permanent operation. Thus measurements with inspection times of 20 – 60 minutes, which are typical for CT, can be performed even in offices. The system control, reconstruction and image processing is realized by a high-power notebook connected via USB. No other hardware is required besides the power supply unit.

Application-adapted design

The CTportable concept provides for possibilities to chose between various design variants. It is possible to equip the system with other detectors and X-ray tubes, e.g. in order to obtain higher resolution or to increase the maximum sample volume. Moreover a vertical stage for Helical CT is available. An extended field of view for the inspection of specimens with larger diameters can be obtained either manually or electrically.

Principle of the Helical Computed Tomography

The trend-setting Helical CT is based on a helicoidal scanning curve. In case of circular scanning (standard CT) the object is only rotated around the rotation axis. On the contrary, the object is additionally shifted along the rotation axis, when realizing a helical data acquisition.

Performance features of the Helical CT

– Prevention of Feldkamp artifacts (figure below).

– Isotropic resolution in all layers of the entire volume.

– Improvement of the spatial resolution along the rotationaxis in the whole measured volume.

– Significantly improved results of the 3D image evaluation dueto enhanced image quality.

– The measuring range height is only limited by the maximumtraverse path.

Characteristics

– Photon counting Medipix2 Quad detector.

– High image quality, no dark noise.

– High dynamic range.

– Basis material analysis, Dual Energy CT.

– Extended field of view function.

– Helical CT for avoiding Feldkamp artifacts.

– Isotropic resolution in all layers.

– Highly accurate dimensional measurement.

– Plug&Play via USB connection.

– Large windows for demonstrations.

– Ergonomic design, easy to handle.

– Compact and light design for easy transport.

– Application-adapted variants.

– Fully shielded system.

Technical Data

X-ray source: 50 kV, 50 W max., spot < 50 μm

Detector: 1024 x 1024 pixels, 48 μm pixel size

Spatial resolution: 18 μm voxel size

Helical function: 50 mm length of stroke

Magnification: up to M = 2,7

Object size: < ø 45 mm, height < 65 mm, < 250 g

Radiation protection: < 0,3 μSv / h (corresponds to a fully shielded system)

Dimensions: 350 mm x 300 mm x 230 mm, < 20 kg