- X-ray Generator

- X-ray Imaging System

- Microfocus X-ray Sources

- Industrial Computed Tomography

- Tube to Tube-sheet Welds Inspection System

- Pipeline Corrosion Inspection System

- Portable X-ray Machine

- Foil Sealing Machine

- Printing Machine

- JIMA

- Add: A1211, No.20 Gangwan Street, Zhongshan Dist., Dalian City, Liaoning Province, P.R.China

- Tel: 0411-82767933

- Fax: 0411-62287077

- Email: han@lind.cn

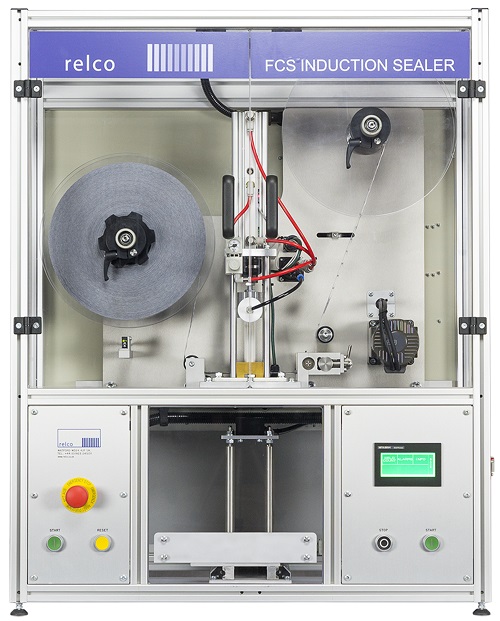

Relco Semi-Automatic foil cutting and sealing machine FCS-1

- Product description: The Relco FCS-1 is a Semi-Automatic foil cutting and sealing machine designed for low volume capless induction sealing applications. Manual functions are limited to container placement and removal wit

Product introduction

The Relco FCS-1 is a Semi-Automatic foil cutting and sealing machine designed for low volume capless induction sealing applications. Manual functions are limited to container placement and removal with foil feeding, cutting, location and sealing being fully automatic. Using this system production speeds of upto 20 containers per minute are possible.

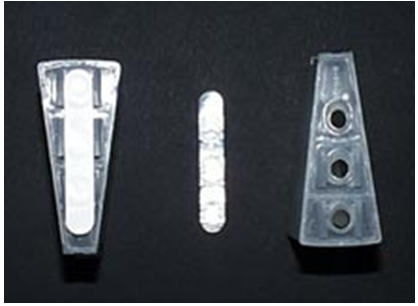

Foil cutting, location and sealing is performed using Relco Punch&Seal ceramic tooling. The Punch&Seal unit is made to order for each individual seal profile and comes in a quick-change cartridge allowing size changes to be made rapidly without the need for tools. This ultra hard punch head has an induction coil built inside of it to allow high speed and very accurate seal cutting, location and induction sealing in a single downward stroke. The machine is PLC controlled with an HMI module on the front panel for ease of use, this gives full control over all sealing parameters to meet the optimum sealing conditions for any container.

This system provides very accurate seal forming and location combined with the superior quality of an induction seal but without the conventional requirement of a cap. Working from reel fed material also keeps consumables costs to a minimum.

Features

* Production speeds of upto 20 cpm

* Relco ceramic Punch&Seal tooling

* Full PLC control with diagnostic and memory function

* Automatic foil indexing & re-wind system

* Vacuum foil location for precision seal placement

|

Requirements |

description |

|

Mains Power |

220-240v a/c Single Phase5A |

|

Compressed Air |

5-7 Bar / 75-100 p.s.i. |

|

Components |

description |

|

Pneumatics |

SMC |

|

Guarding/Safety |

Polycarbonate upper guards, 2-hand start with independent E-Stop circuit |

|

PLC |

Mitsubishi Fx Series |

|

Generators |

Relco P800 (800W) solid state induction generators |

|

Sealing Heads |

Ceramic Punch&Seal cartridges with internal induction coil |

|

Reel Holders |

Quick change Aluminium & Polycarbonate reel carrier with fully adjustable internal friction clutch |

|

Size & Weight |

description |

|

Weight |

45Kg |

|

Dimensions |

810mm x460mmx1010mm |