- X-ray Generator

- X-ray Imaging System

- Microfocus X-ray Sources

- Industrial Computed Tomography

- Tube to Tube-sheet Welds Inspection System

- Pipeline Corrosion Inspection System

- Portable X-ray Machine

- Foil Sealing Machine

- Printing Machine

- JIMA

- Add: A1211, No.20 Gangwan Street, Zhongshan Dist., Dalian City, Liaoning Province, P.R.China

- Tel: 0411-82767933

- Fax: 0411-62287077

- Email: han@lind.cn

VX Exchanger RT of Vision in X

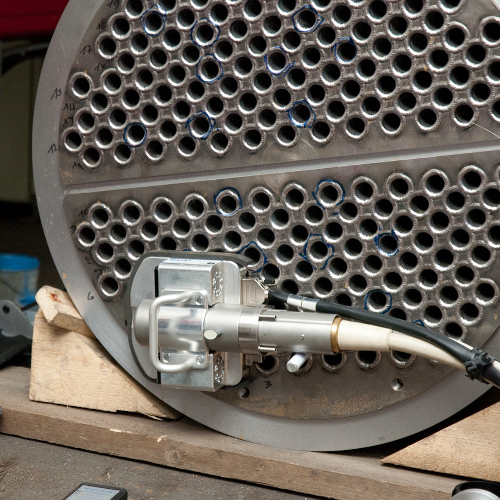

- Product description: inspection of tube to tube-sheet welded joints of tube bundle heat exchanges, boilers or steam generators; post-manufacturing as well as in-sevice.

Product introduction

Applicability: inspection of tube to tube-sheet welded joints of tube bundle heat exchanges, boilers or steam generators; post-manufacturing as well as in-service.

U-type heat exchanger under construction

VX Exchanger RT allows digital radiographic inspection with one-sided access (frontal insertion of X-ray source) and fully replaces the classical film-based method. It allows unparalleled increase of performance in comparison to legacy technology and can be used for metallic materials (e.g. steel, aluminum or titanium alloys) up to tube diameters of40 mm.

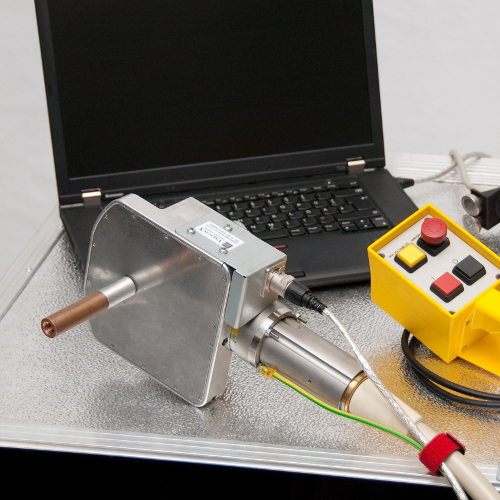

The VX Exchanger RT system (general view)

Advantages overview:

• significant cost and manpower savings:

»10x reduction of inspection time (vs. conventional)

»no consumables (no film, no chemistry, no environmental issues)

• uses no radioactive isotops, so handling of hazardous material (storage and transportation of permanent radioactive source) is eliminated

• smaller restricted access area (2x2 m² is sufficient), hence no disturbance of production processes during manufactoring or shorter shut-down times

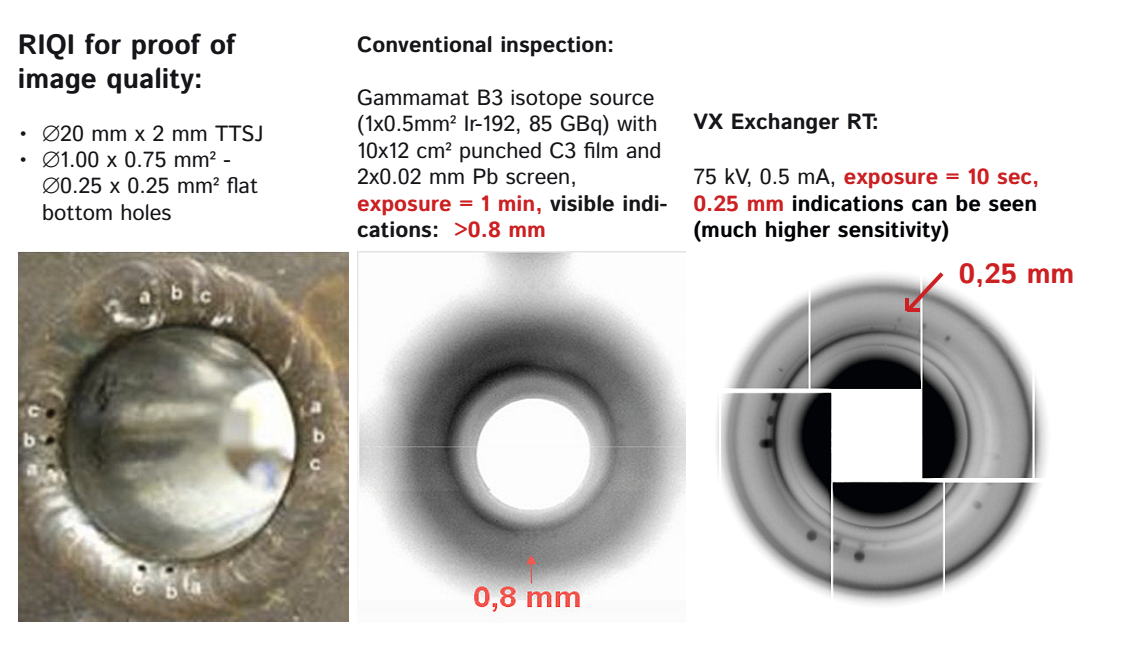

• increased sensitivity (hence wider application area and testing up to higher requirements): 0.2 mm pore diameter in Ti and at least 0.3 mm in low-carbon steel detectable (for comparison: conventional method allows pore detection starting from 0.8 mm in size)

• computer-aided evaluation and documentation

• inspection results instantly known (process optimization during manufacturing possible)

• feasibility of 100% testing (minor added costs, feasible inspection times)

The system consists of:

• custom-made high-sensitivity high-resolution DDA

• pen anode X-ray source and high-voltage generator

• software for controlling of X-ray source and DDA, image processing, display and evaluation, archiving and reporting of the inspection results

• notebook computer

• storage and transport box (fits in a car trunk)

Vision in X industrial imaging GmbHoffers offers VX Exchanger RT as a turn-key system, performs system related and general digital RT training, consultations, long-term service and support.

VX Exchanger RT: 130 kV pen-anode X-ray source with directly converting flat panel detector and computer-aided acquisition, evaluation and archiving

• Incorporates experience collected during 8 years of practical use in field (handling as well as image quality and system reliability)

• Pays-off quickly due to significant reduction of personnel costs, savings on consumables and shorter shut-down time of facilities

Technical specifications:

Max. tube diameter: approx. 40 mm

Pore detectability: 0.3 mm in steel / 0.2 mm in Ti

X-ray energies: 50-130 kV

Max. anode current: 1.66 mA

DDA SRb: 100 µm, max. 200 µm gap

Operating temp.: +10°C..+40°C

Max. relative humidity: 75%

Mains connection: 120/230 VAC, 10/5 A, 60/50 Hz

Total weight: approx. 90 kg

Comes in a storage and transportation box: approx. 80x60x65 cm³ in size or user-specified (please ask)