- X-ray Generator

- X-ray Imaging System

- Microfocus X-ray Sources

- Industrial Computed Tomography

- Tube to Tube-sheet Welds Inspection System

- Pipeline Corrosion Inspection System

- Portable X-ray Machine

- Foil Sealing Machine

- Printing Machine

- JIMA

- Add: A1211, No.20 Gangwan Street, Zhongshan Dist., Dalian City, Liaoning Province, P.R.China

- Tel: 0411-82767933

- Fax: 0411-62287077

- Email: han@lind.cn

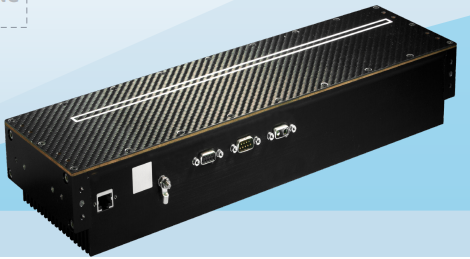

Photon Counting X-Ray Detector XC-Thor Series

- Product description: XC-Thor detectors are dual energy, photon-counting, direct conversion, xray sensors in a robust IP67 rated housing. Employing the very high efficiency direct conversion CdTe-CMOS technology at their c

Product introduction

Product Description

XC-Thor detectors are dual energy, photon-counting, direct conversion, xray sensors in a robust IP67 rated housing. Employing the very high efficiency direct conversion CdTe-CMOS technology at their core, XC-Thor detectors provide outstanding digital image quality for challenging environmental conditions. With the ability to be operated in Frame mode or Time Delayed Summation (TDS) mode this versatile detector can provide solutions for both scanning and single imaging requirements.

Core Technology

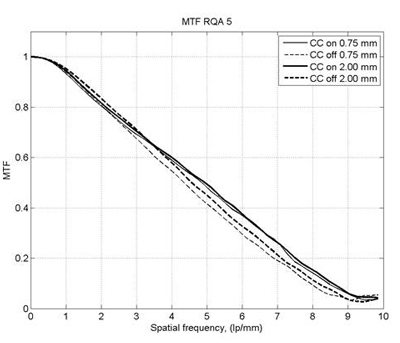

The XC-Thor range has the additional benefit of dual energy acquisition with anti-coincidence technology. During dual energy acquisition the energy of the detected photon is compared to two independent thresholds that are read out separately. The two energy sets can be used for material separation, opening the door to new imaging techniques in both medical and industrial x-ray. Anti-coincidence technology allows superior MTF through attributing single photon signal to the correct pixel

Applicaiton:

With a combination of sensor active areas ranging in length of 8cm and 10cm (longer active areas are available on request) and widths of 1.25cm and 2.5cm (5cm wide active area is available on request). With 0.75mm CdTe standard energy and 2mm CdTe high energy versions, XC-Thor detectors are used in a broad range of applications. Its robust build makes its particularly useful in Weld Integrity Inspection where the detector can be dropped into an existing mechanical scanning system and Field Inspection applications whereenvironmental resilience is important.

Integration:

The XC-Actaeon is connected to the computer via a GigE interface. The detector comes with a fully flexible software development kit which runs on Windows 7 and upwards. The detector is bundled with engineering software which exposes the various functionalities available.

Technical Data:

Dimension L x W x H(mm) : 178 x 140 x 48 ( (without optional cooling system)

Temperature control: Internal Peltier temperature control

X - RAY window: Carbon fiber, 1.5 mm thick

Active area(mm): 80 x 12.8 / 80 x 25.6

Sensor type: Dual-Energy Photon Counting CdTe-CMOS

Sensor thinkness options: 0.75mm : Standard energy applications/2mm : High energy application

Tile gap: 100μm

Pixel size: 100μm

Tube KV range: up to 160kVp normal up to 300kVp with added shielding

Pixel fill factor: 100%

Imaging speed: 300fps ; (TDS): 10,000Line/s

Counter output range: 16bit(Frame)/ 32bit (TDS)

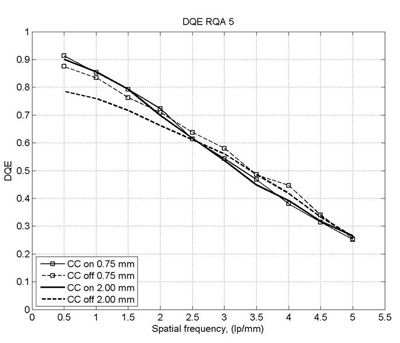

Detective Quantum Efficiency DQE (0) typical : RQA5 spectra, 6μGy, SID 1m 0.75mm CdTe >80% 2.0mm CdTe >80%

Modulation Transfer Function MTF: >75% @ 2lp/mm; >40% @ 5lp/mm

Lag: 0% (after X-ray 6μGy)

Ghosting: <0.1% 1 min after x-rays (6 μGy)

Resolution and DQE for anti-coincidence (CC) on and off